Crankshaft is made of carbon structural steel or nodular cast iron; it is the critical rotating part of engine. When mounted with connecting rod, piston converts linear reciprocating motion into rotating motion. At present, the maximum revolving speed of automotive engine we are familiar with can reach 6000 r/min above, which places more strict requirements on process technique including location consistency, circularity, and straightness of hole-center of different crankshaft, surface roughness, etc.

End-face machining

FMA 07 series face milling cutter, octagon insert with 16 cutting edges, combined with excellent “black diamond ”grade,can achieve super-high economical efficiency and working efficiency.

External turning

Insert edges has stepped appearance,external turning and step machining can be performed in one operation, greatly decrease the turning time and improve working efficiency.

Crankshaft external millingTeeth distribution in radial and axial direction, can realize three side machining, more teeth involved in cutting,greatly improving the working stability and high efficiency.

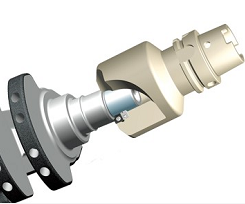

Inclined oil hole machining

Convex milling: Solid carbide four flutes flattened end mill with straight shank, high stability edge treatment and high-rigidity structure design can realize multiple-functions of machining.

Inclined oil hole-making: combined with special coating grade, optimized structure design can achieve high-efficiency drilling machining.

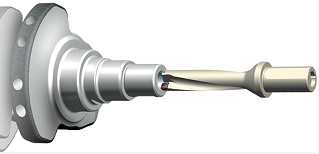

Center countersink machining

ZTD series U drill, good mounting angle,optimized internal structure and firm drill body, can achieve high stable machining while bearing higher feed rate.

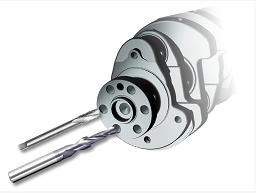

Flange hole-machining

Drilling: Solid carbide step drill,suitable for different high-precision drilling, can provide tailor-made drills as per customer requirements.

Tapping: Newly solid carbide taps and forming taps, according to different materials features, we design the products to meet different working conditions and machining requirements.